SHOP

PRODUCTS

Wright Fan

Maximum uptime, easy refurbishment, and true circularity

Wright Fan 120 mm and 140 mm Modular Systems

Engineered for uptime. Designed for circularity.

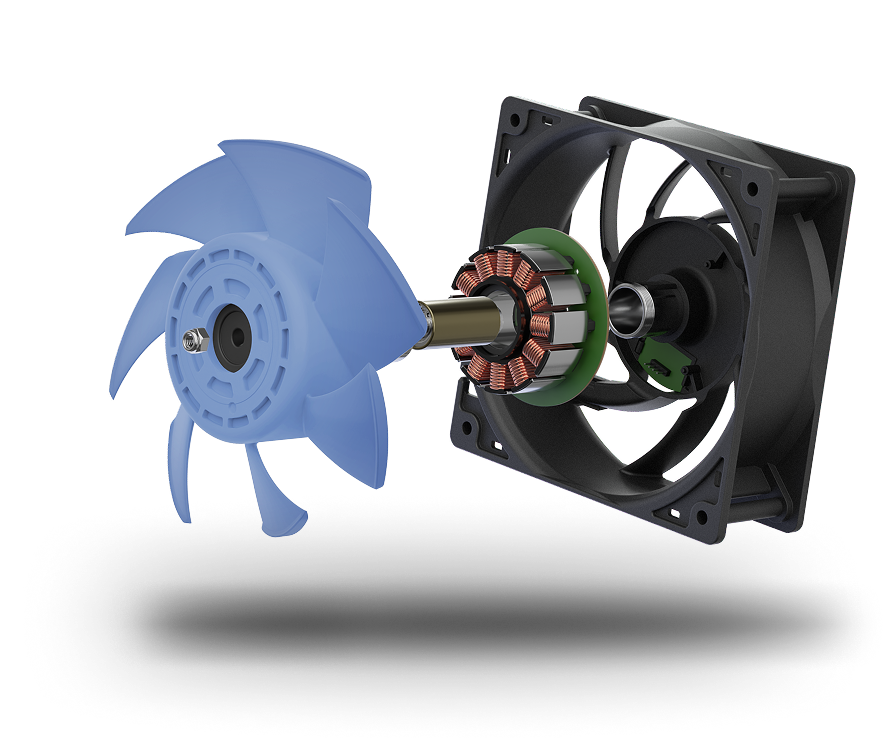

The Wright Fan delivers next-generation airflow performance through a fully modular 4-part design: impeller, motor, bearing, and housing — each replaceable in under 1-minute. Built for data centers and crypto-mining environments, every fan maintains high pressure and airflow under extreme impedance while cutting total lifecycle CO2e by up to 85% through refurbishment and reuse.

Traditional fans fail, forcing full replacements and downtime. The Wright Fan recycles roughly two-thirds of its materials and re-enters service, reducing total cost of ownership by about 50% over five years.

For low-volume customers, Wright One offers an all-inclusive unlimited replacement service plan with an initial hardware fee. This includes logistics, failure replacements, and product upgrades as Wright One continues developing its system — ensuring customers always operate on the latest generation without repurchasing.

Designed in the USA. Assembled for the world. Made to be recycled.

WrightFlow Industrial

Every revolution begins with a spark of efficiency.

A fully modular electric turbine platform that transforms how we think about airflow, efficiency, and propulsion. We're building systems that don't just cool—they scale. From data centers to industrial applications, and ultimately to the skies, Wright One is creating a platform that adapts to the demands of any environment.

Crypto Mining

WrightFlow eliminates airflow limits—expand fan stages to boost exhaust and maintain perfect pressure.

Data Centers

Fully modular, service-maintained, and performance-tuned cooling with free upgrades as you scale.

Industrial Ventilation

Piloting adaptive systems in self-storage to launch our commercial line—join our Q2 2026 rollout.

Technology

Fails Harder. Comes Back Stronger. 4x Recycled in the USA.

In industries like automotive and aerospace, circular manufacturing has already replaced the 'use-and-throw' mindset. Wright One applies that same model to Bitcoin mining—refurbishing and re-using each fan module up to 4x before full end-of-life recycling at its Cedar Park, Texas facility.

- •Modularity: Swap failed parts in under a minute.

- •Circular Tariff: 4x reuse cuts tariff impact by 75%.

- •Transparency: Real-time uptime, failure, and CO₂e tracking.

Live Stats

Real-time uptime, failure, and CO₂e tracking.

Fans Deployed

90

Fans Failed

4

Avg. Failure Rate

4.4%

Avg. Downtime

N/A

Failures & Transparency

What we Track

Failures by type

We categorize every fan failure across motor, impeller, bearing, and electronics to identify root causes by environment, batch, and operating conditions—building a predictive reliability model over time.

Downtime impact

Each event is tracked by its effect on uptime and throughput. Our analytics quantify lost cooling hours and associated cost per site, giving operators a clear ROI on reliability improvements.

Resolution actions

Every replacement, refurbishment, and design improvement feeds back into the system. Customers see exactly how each issue was resolved and how their next batch performs better.

How we Resolve

QR-tracked units

Every Wright Fan carries a laser-etched QR code that links to its serial history. Each scan logs performance, uptime, and environmental data—creating a traceable lifecycle for every module deployed.

Root cause analysis

Failures trigger automatic data collection across site conditions, operating loads, and component age. This allows our engineers to pinpoint the cause—whether it’s heat, dust, vibration, or supplier variance.

Design/supplier fix

Insights from field data feed directly into design and supplier updates. Each issue resolved strengthens the next generation of Wright Fan, closing the loop between analytics and production.

Replacements

In Wright One’s service model, every failure is automatically replaced—no approvals, no limits. Customers ship modules back using prepaid labels, and we send a fresh box of new parts immediately.

Flying Cars Start Here.

Every fan we build cools your systems today, while the data we gather fuels tomorrow's airborne vehicles.

Wright Fan turns today's cooling power into tomorrow's motion.